Heat pipe cooling for Li-ion battery pack is limited by gravity, weight and passive control. Currently, air cooling, liquid cooling, and fin cooling are the most popular methods in EDV applications. Some HEV battery packs, such as those in the Toyota Prius and Honda Insight, still use air cooling.

Contact online >>

This paper summarized the development status of the latest power lithium-ion battery liquid cooling system, different types of liquid cooling system were compared, the performance comparison and application analysis of different coolants were also carried out, and the advantages and disadvantages of various cooling system structures were listed.

Thermal management for the prismatic lithium-ion battery pack by immersion cooling with Fluorinated liquid. Author links open overlay panel Yang Li a, Minli Bai a, Zhifu Zhou b, Heat and mass transfer modeling and assessment of a new battery cooling system. Int. J. Heat Mass Transf., 126 (2018), pp. 765-778. View PDF View article View in

In this study, the effects of battery thermal management (BTM), pumping power, and heat transfer rate were compared and analyzed under different operating conditions and cooling configurations for the liquid cooling plate of a lithium-ion battery. The results elucidated that when the flow rate in the cooling plate increased from 2 to 6 L/min, the average

A comparative investigation of two-phase immersion thermal management system for lithium-ion battery pack. J. Clean. Prod., 434 (2024), Article 140472. Numerical investigation on manifold immersion cooling scheme for lithium ion battery thermal management application. Int. J. Heat Mass Transf., 190 (2022), Article 122750.

In the future, lithium-ion battery thermal management technology combining multiple cooling methods is the main development direction. Suitable thermal management technologies can be selected and combined based on the advantages and disadvantages of different cooling technologies to meet the thermal management needs of different users.

Immersion cooling for lithium-ion batteries – A review. Author links open overlay panel Charlotte Roe a, Xuning Feng b, Gavin White c, For the air cooling system, the battery temperature reached 80 °C at 10C within 5 cycles and 90 °C at 20C after 2 cycles. Conversely, the immersion cooling system exhibited excellent thermal performance

The performance, safety, and cycle life of lithium-ion batteries (LiBs) are all known to be greatly influenced by temperature. In this work, an innovative cooling system is employed with a Reynolds number range of 15,000 to 30,000 to minimize the temperature of LiB cells. The continuity, momentum, and energy equations are solved using the Finite Volume

Recently, the need for thermal management of lithium-ion batteries in electrical transportation engineering has received increased attention. To get maximum performance from lithium-ion batteries, battery thermal management systems are required. This paper quantitatively presents the effects of several factors on both maximum battery temperature and temperature

With the increasing application of the lithium-ion battery, higher requirements are put forward for battery thermal management systems. Compared with other cooling methods, liquid cooling is an efficient cooling method, which can control the maximum temperature and maximum temperature difference of the battery within an acceptable range.

1 INTRODUCTION. Lithium ion battery is regarded as one of the most promising batteries in the future because of its high specific energy density. 1-4 However, it forms a severe challenge to the battery safety because of the fast increasing demands of EV performance, such as high driving mileage and fast acceleration. 5 This is because that the battery temperature

The cooling system causes uniform temperature distributions, and the maximum temperature of battery pack reduced by 5 C. Thermal management of lithium -ion battery cell is investigated during short process to limit the high temperature effect on the system [9]. The shorting resistance causes large amount of heat and increases the cell temperature.

The use of rechargeable lithium-ion batteries in electric vehicles is one among the most appealing and viable option for storing electrochemical energy to conciliate global energy challenges due to rising carbon emissions. However, a cost effective, efficient and compact cooling technique is needed to avoid excessive temperature build up during discharging of

The power battery is an important component of new energy vehicles, and thermal safety is the key issue in its development. During charging and discharging, how to enhance the rapid and uniform heat dissipation of

The continuous low temperature in winter is the main factor limiting the popularity of electric vehicles in cold regions. The best way to solve this problem is by preheating power battery packs. Power battery packs have relatively high requirements with regard to the uniformity of temperature distribution during the preheating process. Aimed at this problem,

Heat generation and accumulation during working schemes of the lithium-ion battery (LIB) are the critical safety issues in hybrid electric vehicles or electric vehicles. Appropriate battery thermal management is necessary for ensuring the safety and continuous power supply of rechargeable LIB modules. In this study, thirty cylinder 18650-type cells were

Efficient thermal management of lithium-ion battery, working under extremely rapid charging-discharging, is of widespread interest to avoid the battery degradation due to temperature rise, resulting in the enhanced lifespan. Herein, thermal management of lithium-ion battery has been performed via a liquid cooling theoretical model integrated with

Optimization study of a Z-type airflow cooling system of a lithium-ion battery pack Santosh Argade; Santosh Argade (Conceptualization, Formal analysis, Investigation, Methodology, Visualization, Writing – original draft) 1. Department of Sustainable Energy Engineering, Indian Institute of Technology Kanpur

As a result, a reliable and effective battery cooling system with suitable equipment and mechanism is crucial to eliminate safety issues such as thermal runaways and explosions [[121], [122] Fig. 1 a is a typical Lithium-ion battery passive air-cooling BTMS in which battery cells are regularly aligned inside the battery pack. Outside air

This work aims to show the most used lithium-ion battery pack cooling methods and technologies with best working temperature ranges together with the best performances. Yang, Q. Thermal performance of cylindrical Lithium-ion

Choosing a proper cooling method for a lithium-ion (Li-ion) battery pack for electric drive vehicles (EDVs) and making an optimal cooling control strategy to keep the temperature at a optimal range of 15 °C to 35 °C is essential to increasing safety, extending the pack service life, and reducing costs.

Thermal management is indispensable to lithium-ion battery pack esp. within high power energy storage device and system. To investigate the thermal performance of lithium-ion battery pack, a type of liq. cooling method based on mini-channel cold-plate is used and the three-dimensional numerical model was established in this paper.

The most effective cooling system to control the operating temperature of the battery pack over the last several years is a liquid cooling battery thermal manag. Analysis of thermal behavior on lithium-ion battery module using liquid cooling battery thermal management system Rina Dewi Mayasari;

Choosing a proper cooling method for a lithium-ion (Li-ion) battery pack for electric drive vehicles (EDVs) and making an optimal cooling control strategy to keep the temperature at a optimal

This work aims to show the most used lithium-ion battery pack cooling methods and technologies with best working temperature ranges together with the best performances. Yang, Q. Thermal performance of cylindrical Lithium-ion battery thermal management system based on air distribution pipe. Int. J. Heat Mass Transf. 2019, 131, 984–998

One of the key technologies to maintain the performance, longevity, and safety of lithium-ion batteries (LIBs) is the battery thermal management system (BTMS). Owing to its excellent

This analysis uses the model created by user "Nilesh" on GrabCAD and represents a 10s3p ( 10 rows of 3 cells) of Li-Ion cell battery pack and a Battery Management System "BMS" represented by an electronics unit

This analysis uses the model created by user "Nilesh" on GrabCAD and represents a 10s3p ( 10 rows of 3 cells) of Li-Ion cell battery pack and a Battery Management System "BMS" represented by an electronics unit board at the extreme of the battery pack. The first proposed design of the casing hosting this battery pack consists of an 80mm

Therefore, the current lithium-ion battery thermal management technology that combines multiple cooling systems is the main development direction. Suitable cooling methods can be selected and combined based on the advantages and disadvantages of different cooling technologies to meet the thermal management needs of different users. 1. Introduction

Batteries have been widely recognized as a viable alternative to traditional fuels for environmental protection and pollution reduction in energy storage [1].Lithium-ion batteries (LIB), with their advantages of high energy density, low self-discharge rate, cheap maintenance and extended life cycle, are progressively becoming dominant in battery world [2, 3].

Thermal Performance Analysis of Liquid Cooling System in Lithium-ion Battery. December 2023 · International Journal of Innovative Research in Advanced Engineering. Ambadas Waghmare;

Coolant improvement The liquid cooling system has good conductivity, allowing the battery to operate in a suitable environment, which is important for ensuring the normal operation of the lithium-ion battery.

The basic simplified model of the lithium-ion battery pack, which is equipped with a series of novel cooling systems and includes a single lithium-ion battery and different types of cooling structures, is shown in Fig. 1. The simplified single lithium-ion battery model has a length w of 120 mm, a width u of 66 mm, and a thickness v of 18 mm.

Given the growing demand for increased energy capacity and power density in battery systems, ensuring thermal safety in lithium-ion batteries has become a significant challenge for the coming decade. Effective thermal management plays a crucial role in battery design optimization. Air-cooling temperatures in vehicles often vary from ambient due to

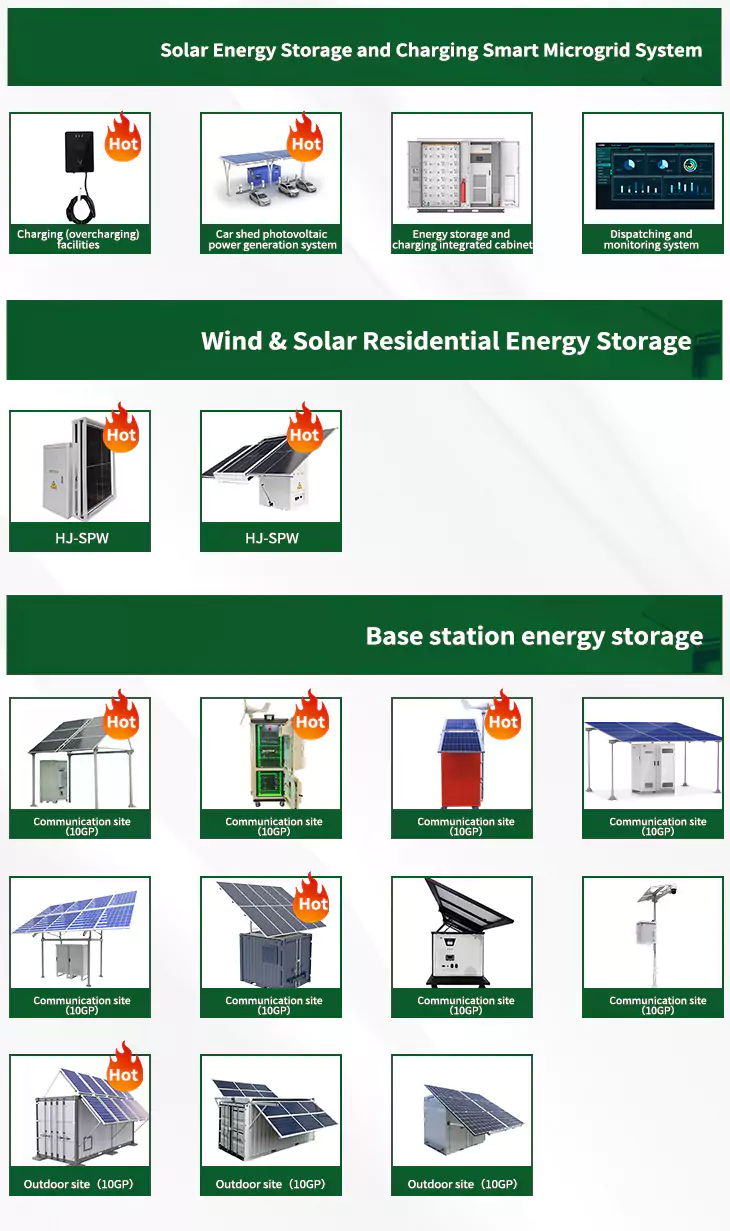

As the photovoltaic (PV) industry continues to evolve, advancements in cooling system for lithium ion battery have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient cooling system for lithium ion battery for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various cooling system for lithium ion battery featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

Enter your inquiry details, We will reply you in 24 hours.