non-uniform strain adjustable gap height good for testing boundary effects like slip .

Creep‐ringing

Norman

&

Ryan’s

work

here

(fibrin,

jamming)

Good

tutorial

by

Ewoldt

&

McKinley

(MIT)

.

Limits

of

linear

viscoelasc

regime

in

desired

frequency

range

using

amplitude

sweeps

=>

yield

stress/strain,

crical

stress/strain

Test

for

me.

Stress/strain

ramps

with

constant

rate

Pre‐stress

measurements,

i.e.

small

stress

oscillaons

around

a

constant

(pre‐)stress

Pre‐strain

measurements

Transient

responses

in

LAOS

(talk.Strain‐control vs stress‐control • Strain‐controlled state typically considered beer defined • Stress‐controlled rheometers have beer torque sensivity • Strain‐controlled rheometers can probe higher frequencies • BUT.nowadays, feedback loops are fast enough

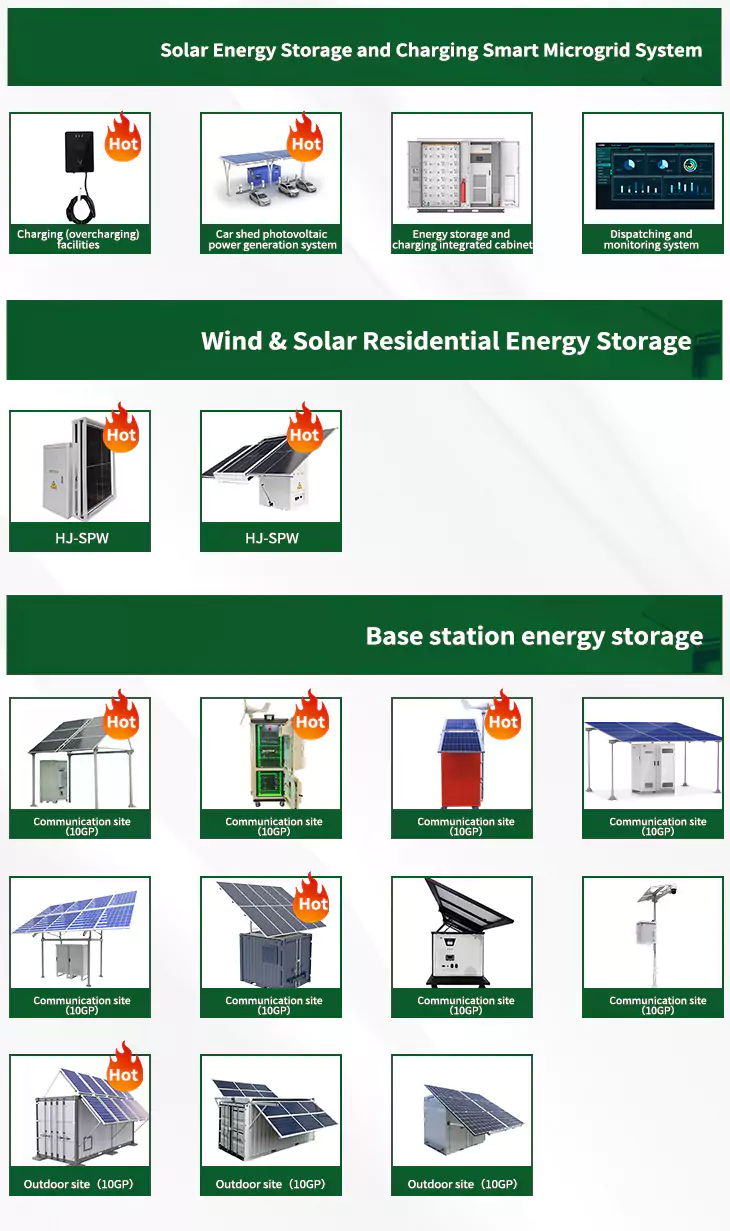

Contact online >>

To do so, a single reference temperature is selected from the data (e.g. 95°C) and the storage modulus (E'') values at this temperature for each frequency in the series (e.g. 20, 10, 5, 2, 1, 0.5, 0.2, 0.1 Hz) are constructed into a "reference data set" of E'' versus frequency.

From Equation (5), the activation energy of the samples is proportional to the slope of log a T versus 1/ T plot when the testing temperature is above the glass transition temperature as shown in Figure 13 (temperature range from 0 to 100 °C) and the magnitude of the activation energy of the sample can be calculated according to the slope of

If one can generate a modulus scan over a wide enough frequency range (Fig. 18), the plot of storage modulus versus frequency appears like the reverse of a temperature scan. The same time–temperature equivalence discussed above also applies to modulus, as well as compliance, tan delta, and other properties.

In this work, a variable activation energy model of ultrasonic curing was established by utilizing the iso-conversional method, including the activation energy of the thermal effect and activation

Download scientific diagram | Storage modulus (a), loss modulus (b) and tan δ (c) versus temperature for the from publication: Cure Kinetics and Properties of High Performance Cycloaliphatic

Download scientific diagram | Storage modulus and tan delta versus temperature for all adhesives before and after exposed to 30°C/95%RH from publication: Creep Behavior of Epoxy-Based Adhesive

Download scientific diagram | DMA plots of (a) tanδ and (b) storage modulus versus temperature obtained for the srrPET and mPET specimens at a frequency of 1 Hz from publication: Long-term creep

However, we show that the analysis of internal network dynamics based on the thermally activated exchange does not have any such transition temperature, and it is merely a matter of time (or deformation rate) at which the plastic flow is detectable—again in full analogy with silicate glass.

The second critical temperature was close to the mechanical glass transition temperature. The activation energy values were 13.1, 69.6, and 72.4 kJ/mole for phase 1, phase 2 and phase 3, respectively.

22.4.1.2.3.1. Storage modulus versus angular frequency. It is also considered as the tendency of a material to store energy [244]. Loss modulus (E'''') The storage modulus as a function of temperature at six different maleic acid concentrations is shown in Fig. 12.11. These are compared to the storage modulus of a miniemulsion polymer

It is well known that the mechanical properties of polymers are highly dependent on the temperature and strain rate, or frequency. Dynamic Mechanical Analysis (DMA) is a valuable tool for evaluating frequency- and temperature dependence of the complex modulus [9, 10].Essential features that can be measured include storage modulus, loss modulus, tan delta,

From the profile of the activation energy, the three discrete relaxation modes with various activation energies, i.e., α relaxation (7.98 eV) is linked to the cooperative motion of

"activation barrier" for solid-phase reactions, deformation, flow or creep, acoustic damping, physical aging changes, and gas diffusion into polymers as the activation energies for the

It demonstrates the influence of temperature on the storage modulus of composite samples and demonstrates how the storage modulus vs. temperature curve may be used to determine the stiffness

The storage modulus'' change with frequency depends on the transitions involved. Above the T g, the storage modulus tends to be fairly flat with a slight increase with increasing frequency as it is on the rubbery plateau. The change in the region of a transition is greater.

Storage modulus; measures stored energy and represents elastic portion: The glass transition temperature can be determined using either the storage modulus, complex modulus, or tan δ (vs temperature) depending on context and instrument; because these methods result in such a range of values (Figure (PageIndex{6}) ), the method of

The response of those materials is dependent upon the stress-strain rate and the temperature itself. This temperature and time-dependent material behavior is called viscoelasticity. ΔH is the apparent activation energy of the process, kT is the thermal energy, where the in-phase modulus G 1 is defined as the storage modulus and the out

The storage modulus is often times associated with "stiffness" of a material and is related to the Young''s modulus, E. The dynamic loss modulus is often associated with "internal friction" and is sensitive to different kinds of molecular motions, relaxation processes, transitions, morphology and other structural heterogeneities.

the activation energy of the rate controlling diffusion mechanism . Equation (1) is known as Dorn''s equation (Bird et al., 1969) and is often simplified as: shear modulus temperature coefficient : G 0 = 1.9 Mpsi and G 1 = 8.1 kpsi/°K for both alloys of 60Sn-40Pb and 62Sn-36Pb-2Ag .

From Equation (5), the activation energy of the samples is proportional to the slope of log a T versus 1/ T plot when the testing temperature is above the glass transition temperature as shown in Figure 13 (temperature

The time–temperature shift factor can also be described in terms of the activation energy (E a). By plotting the shift factor a T versus the reciprocal of temperature (in K), the slope of the curve can be interpreted as E a /k, where k is the Boltzmann constant = 8.64x10 −5 eV/K and the activation energy is expressed in terms of eV.

Download scientific diagram | Storage modulus (a), loss modulus (b) and tan δ (c) versus temperature for the from publication: Cure Kinetics and Properties of High Performance Cycloaliphatic

Moving from very low temperature, where the molecule is tightly com-pressed, to a higher temperature, although its activation energy is only 30-40 J/g. Boyer21 and Heijober7 showed that on the storage modulus directly preceding the drop that corresponds to

Equation (7) shows that the complex modulus obtained from a dynamic mechanical test consists of "real" and "imaginary" parts. The real (storage) part describes the ability of the material to store potential energy and release it upon deformation.

The arrhenius plot shows how activation energy and temperature affect the sensitivity of the reaction rate; Practice Problems. 1. T/F The E a calculated from the Arrhenius equation gives an exact value. 2. Describe the relationship between temperature and E a and give examples. 3. Using the following information:

Also, mainly at low frequencies, polyethylene had the higher values of storage modulus (325 Pa), loss modulus (937 Pa) and complex viscosity (9,740 Pa.s). However, blends had values lying between those of the two homopolymers without any improvement in the storage modulus, loss modulus or complex viscosity.

Calculation of the temperature dependence of the activation energy of the glass transition process U(T) of amorphous organic polymers and inorganic glasses with the use of the Williams-Landel

Fig. 3 demonstrates the effect of temperature on storage modulus and tan δ over the range of 25 – 400 1 C as measured by DMA. (i.e. before the plateau) has higher activation energy for

These materials exhibit stable storage modulus (100 ~ 102 MPa) with high energy dissipation (loss factor > 0.4) over a broad frequency range (10−1 ~ 107 Hz)/temperature range (−35 ~ 85°C).

where, R is the gas constant (= 8.31 J/mol K), T 0 is the standard temperature (293 K). The activation energy A new model for the master curve was proposed by showing the relationship between storage modulus and time/temperature. The shift factors below and above the glass transition temperature were considered. The epoxy-carbon composite

If one can generate a modulus scan over a wide enough frequency range (Fig. 18), the plot of storage modulus versus frequency appears like the reverse of a temperature scan. The same time–temperature equivalence discussed above also applies to modulus, as well as compliance, tan delta, and other properties.

Figure 4.13 shows the storage modulus (G'') and loss modulus (G") vs. frequency for various temperatures such as 25°C, 35°C, 45°C, and 55°C. Similarly, as the temperature increases, the loss tangent increases; it indicates that the material dissipates more energy at a higher temperature. In the developed media, the addition of abrasive

As the photovoltaic (PV) industry continues to evolve, advancements in storage modulus versus temperature activation energy have become critical to optimizing the utilization of renewable energy sources. From innovative battery technologies to intelligent energy management systems, these solutions are transforming the way we store and distribute solar-generated electricity.

When you're looking for the latest and most efficient storage modulus versus temperature activation energy for your PV project, our website offers a comprehensive selection of cutting-edge products designed to meet your specific requirements. Whether you're a renewable energy developer, utility company, or commercial enterprise looking to reduce your carbon footprint, we have the solutions to help you harness the full potential of solar energy.

By interacting with our online customer service, you'll gain a deep understanding of the various storage modulus versus temperature activation energy featured in our extensive catalog, such as high-efficiency storage batteries and intelligent energy management systems, and how they work together to provide a stable and reliable power supply for your PV projects.

Enter your inquiry details, We will reply you in 24 hours.